FFSim

What is FFSim?

FFSim is a Foundation Fieldbus simulation tool that connects to any Foundation Fieldbus H1 host, simulating any number and type of Foundation Fieldbus devices. FFSim Simulator may be used during configuration development and Factory Acceptance Test (FAT) to simulate Foundation Fieldbus segment devices. This allows for full simulation of the system from controller, H1 card to field. Another common application for FFSim is maintenance and operator training simulators. FFSim allows for virtual device decommissioning, replacement and commissioning in a control system vendor neutral package.

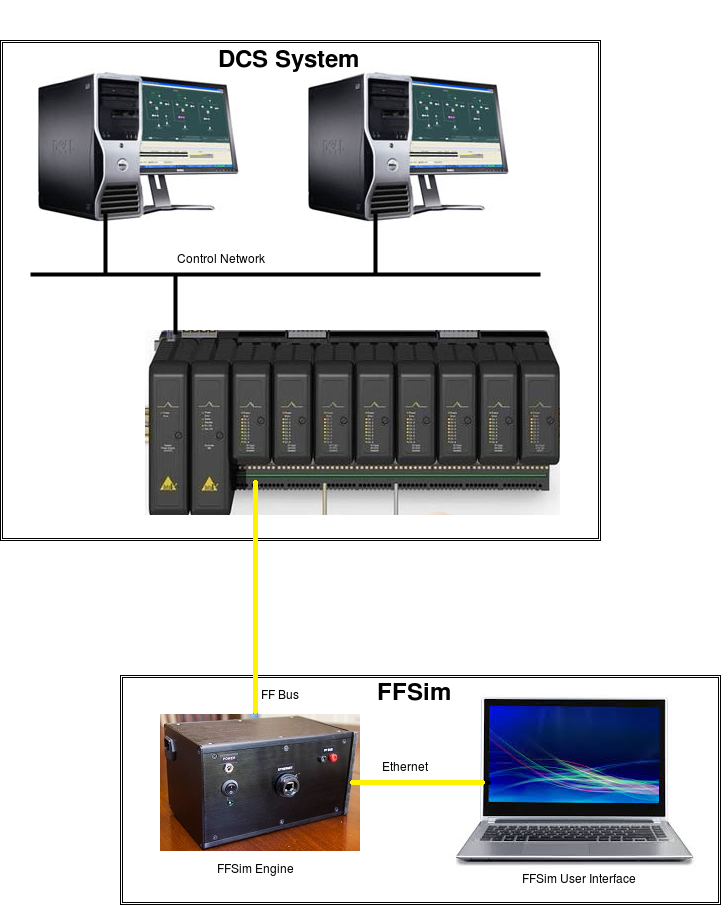

Architecture Diagram

FFSim is comprised of FFSim Engine and FFSim User Interface. FFSim Engine is connected with DCS system H1 card through FF Bus. FFSim User Interface is connected with FFSim Engine by an Ethernet cable for user configuration and operation.

Foundation Fieldbus Common Concerns

- The technology is too complex and difficult to understand

- Control systems with Foundation Fieldbus devices can’t be fully tested and validated until final installation

- Foundation Fieldbus is too slow (especially when commissioning many devices)

FFSim Key Features

FFSim is a Foundation Fieldbus Simulation tool that simulates all Foundation Fieldbus devices present in the plant, providing quasi-plant environment in the office or fabrication shop during configuration development stage and FAT (Factory Acceptance Test). It allows:

- End user training including operations and maintenance personnel

- implementation missteps can be caught and corrected during development and testing rather than during commissioning.

- “Demystification” of Foundation Fieldbus technology. It is easier to understand a working system

- “Demystification” of Foundation Fieldbus technology. It is easier to understand a working system

- Full control strategy testing. It doesn’t matter if control is in the system, the field, or hybrid, FFSim can facilitate testing all cases. Any improper segment loading can be determined at development, before shipping system to site.

- FFSim can showcase “control in the field”, with full behavior of the segment simulated

- FFSim can maintain commissioning status. Once commissioned in the office or fabrication shop, it is not necessary to re-commission on site.

FFSim Advantages

- FFSim is compact. One small box can connect as many as 4 Foundation Fieldbus segments and hundreds of devices.

- FFSim can connect with any Foundation Fieldbus H1 host. It’s vendor neutral.

- FFSim can emulate any Foundation Fieldbus compliant transmitters, valves and motors. As long as the device information is imported, the FFSim will automatically generate all devices on segments.

- The simulated devices can be commissioned and downloaded with any control system host.

- Once simulated devices are commissioned and downloaded, the operations is similar to real devices connected to the control system. Foundation Fieldbus segment loading and complete control strategy can be fully tested.

- Once Foundation Fieldbus segments are commissioned by using FFSim during FAT, commissioning status is maintained. It is not necessary to re-commission the Foundation Fieldbus devices during plant start-up when real devices are powered up, which will completely get rid of the time on Foundation Fieldbus device commissioning and significantly reduce the plant start-up time.